For our full range of products and services, choose the relevant catalogue.

Overview

Common Applications

Key Features

Material Profile

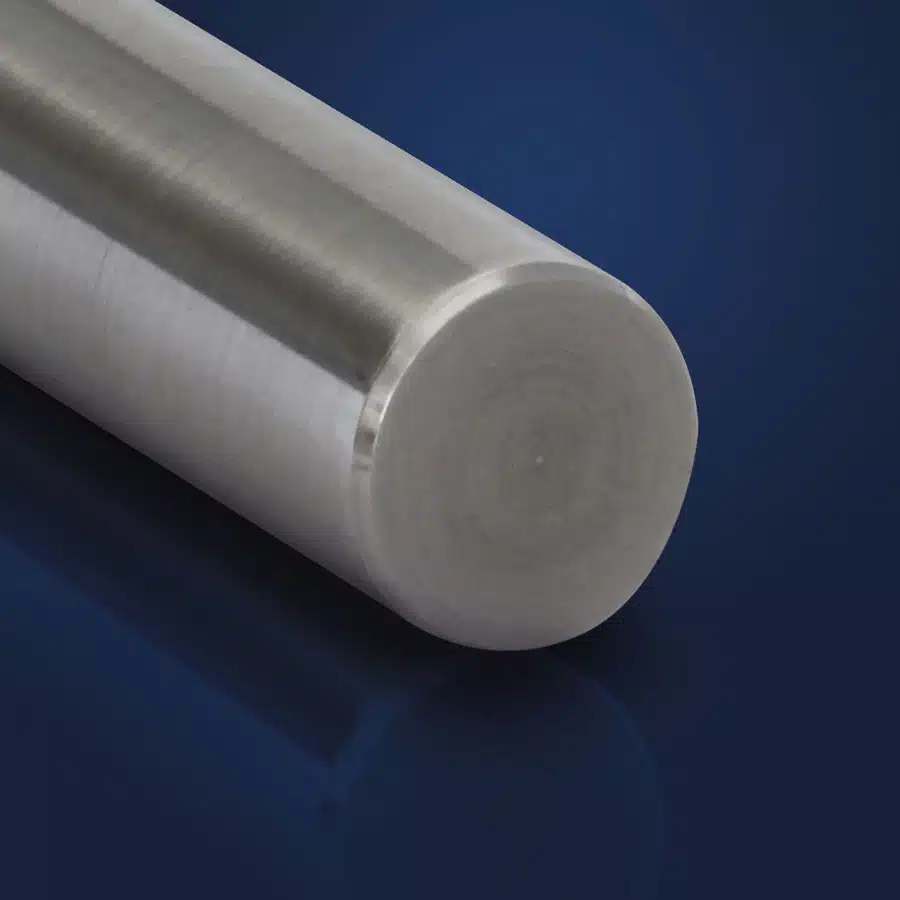

Aluminium 6082-T6

Aluminium 6082-T6

Aluminium 6082-T6

Aluminium 6082-T6

Aluminium 6082-T6

Aluminium 6082-T6

Aluminium 6082-T6

Aluminium 6082-T6

Aluminium 6082-T6

Aluminium 6082-T6

Aluminium 6082-T6

Aluminium 6082-T6

Aluminium 6082-T6

Aluminium 6082-T6

Aluminium 6082-T6

Aluminium 6082-T6

Aluminium 6082-T6

Aluminium 6082-T6

Chemical Composition

| Element | Symbol | Range % |

| Aluminium | Al | Balance |

| Silicon | Si | 0.7-1.3 |

| Magnesium | Mg | 0.6-1.2 |

| Manganese | Mn | 0.4-1.0 |

| Iron | Fe | 0.50 max |

| Chromium | Cr | 0.25 max |

| Zinc | Zn | 0.2 max |

| Copper | Cu | 0.1 max |

| Titanium | Ti | 0.1 max |

| Others | 0.15 max |

Mechanical Properties

| Metric Values | Imperial Values | |

| Tensile Strength Min | 205 N/mm² | 30000 psi |

| Yield Strength Min | 110 N/mm² | 16000 psi |

| Elongation Min | 12% | 12% |

| Hardness Min | 70 BHN | 70 BHN |

Comparative Specifications

Quality Management

Quality materials, delivered to standard.

Kormax is ISO certified for ISO 9001, ISO 14001, and ISO 45001.

All Kormax products come with batch certifications.

Why Choose Us

As a fourth-generation family-owned business, Kormax brings over 75 years of Foundry and Engineering Metals experience to your project.

Kormax operates in various sectors across the world, utilising our leading engineering, manufacturing, and global distribution capabilities to offer world-class solutions for engineers.

Expert Advice

Trusted advice on metal and profile selection for your application

Unique Range

Unique range of quality products, in industry specific profiles and sizes

Top-tier Foundries

Global top-tier supply network with the ability to source specific sizes and metals

Supply Security

Custom supply options and to enhance your supply continuity

Quality Management

ISO Certified for ISO 9001, ISO 14401 and ISO 45501 ensures quality systems are in place

Competitive Pricing

With a wide supplier network, Kormax can balancing quality and value