For our full range of products and services, choose the relevant catalogue.

Overview

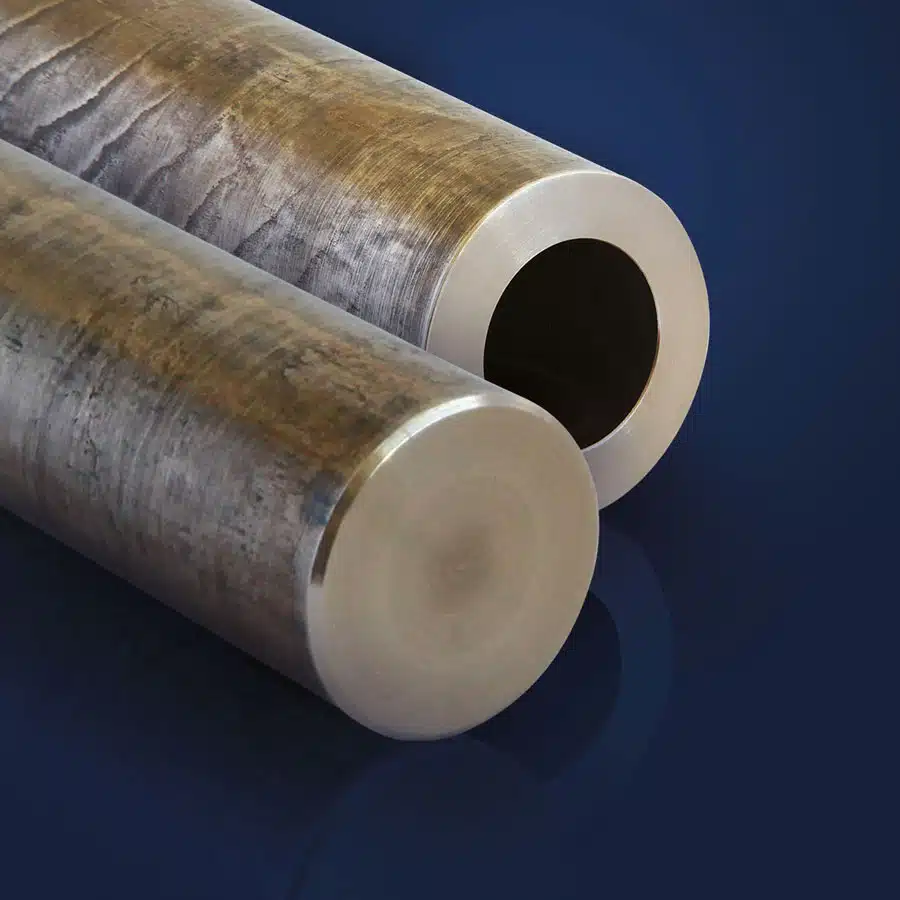

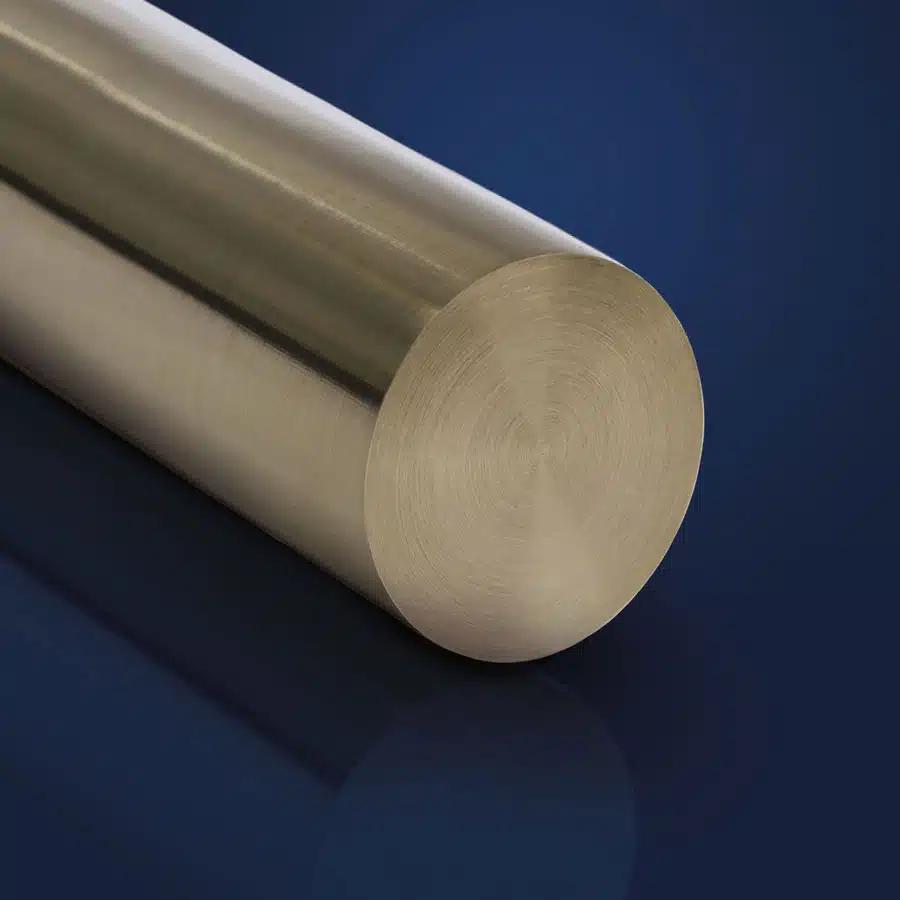

Alloy 954 is a high strength aluminium bronze that is widely used in heavy duty applications such as forestry, mining, construction & marine.

It is a very hard material which has excellent strength and wear resistance, yet still retains good machining properties.

Alloy 954 also has good resistance to impact loading, but it should be noted that proper lubrication is necessary to prevent metal to metal contact. Inadequate lubrication is likely to cause scoring or ‘galling’, and consequent damage to the

bronze component and/or other moving parts. General corrosion resistance is good but de-luminification may occur under some circumstances.

All Kormax 954 Aluminium Bronze is manufactured using finely controlled continuous or centrifugal casting techniques to ensure that hardness and strength is superior to sand-casting methods. This also means that the material has a fine grain structure and is free from porosity.

Common Applications

Key Features

Material Profile

954 Aluminium Bronze

954 Aluminium Bronze

954 Aluminium Bronze

954 Aluminium Bronze

954 Aluminium Bronze

954 Aluminium Bronze

954 Aluminium Bronze

954 Aluminium Bronze

954 Aluminium Bronze

954 Aluminium Bronze

954 Aluminium Bronze

954 Aluminium Bronze

954 Aluminium Bronze

954 Aluminium Bronze

954 Aluminium Bronze

954 Aluminium Bronze

954 Aluminium Bronze

954 Aluminium Bronze

Chemical Composition

| Element | Symbol | Range % | Nominal % |

| Aluminium | Al | 10.0 – 11.5 | 10.5 |

| Iron | Fe | 3.0 – 5.0 | 4.0 |

| Nickel | Ni | 1.5 maximum | 0.5 maximum |

| Manganese | Mn | 0.5 maximum | |

| Copper | Cu | Balance |

Mechanical Properties

| Metric Values | Imperial Values | |

| Tensile Strength Min | 586 N/mm² | 85000 psi |

| Yield Strength Min | 221N/mm² | 32000 psi |

| Elongation Min | 12% | 12% |

| Hardness Min | 170 BHN | 170 BHN |

Comparative Specifications

Machining Allowances

Hollow Bars

| Size Range | OD Allowance | ID Allowance |

| up to 3″ | +0.053″ to +0.073″ | -0.108″ to -0.154″ |

| 3-1⁄4″ to 4″ | +0.079″ to +0.109″ | -0.108″ to -0.174″ |

| 4-1⁄4″ to 5-1⁄2″ | +0.120″ to +0.160″ | -0.125″ to -0.221″ |

| 5-3⁄4″ to 6-1⁄4″ | +0.163″ to +0.214″ | -0.135″ to -0.231″ |

| 6-1⁄2″ to 10″ | +0.180″ to +0.230″ | -0.190″ to -0.286″ |

| Above 10″ | +0.125″ | -0.125″ |

Flat Bars

| Bar Width | Thickness Allowance | Width Allowance |

| Up to 5-1⁄2″ | +0.067″ to +0.107″ | +0.043″ to +0.083″ |

| Above 6″ | +0.087″ to +0.127″ | +0.063″ to +0.113″ |

Quality Management

Quality materials, delivered to standard.

Kormax is ISO certified for ISO 9001, ISO 14001, and ISO 45001.

All Kormax products come with batch certifications.

Why Choose Us

As a fourth-generation family-owned business, Kormax brings over 75 years of Foundry and Engineering Metals experience to your project.

Kormax operates in various sectors across the world, utilising our leading engineering, manufacturing, and global distribution capabilities to offer world-class solutions for engineers.

Expert Advice

Trusted advice on metal and profile selection for your application

Unique Range

Unique range of quality products, in industry specific profiles and sizes

Top-tier Foundries

Global top-tier supply network with the ability to source specific sizes and metals

Supply Security

Custom supply options and to enhance your supply continuity

Quality Management

ISO Certified for ISO 9001, ISO 14401 and ISO 45501 ensures quality systems are in place

Competitive Pricing

With a wide supplier network, Kormax can balancing quality and value

Related Products

630 Nickel Aluminium Bronze

Alloy C63000 is a high-quality extruded material widely used in tough, demanding and corrosive environments. Its exceptional toughness means it is used in applications such as bushings for aircraft landing gear and hydraulic bushings for earth moving equipment.

The nickel content in this material means that it has superior corrosion resistance to marine conditions. Nickel aluminium also has high strength and good wear resistance, making it suitable for bearings, gears and other components with heavy loads and slow speeds. Good lubrication and alignment are essential in bushing applications to ensure optimum performance.

The chemical composition of C63000 is very similar to AB2 Bronze. However, being extruded means it has superior tensile strength, hardness and ductility. A further advantage with this material being extruded is that the diameter quoted is “on size” and has a clean surface finish making it an ideal solution for marine fasteners and fittings such as keel bolts, studs and other parts.