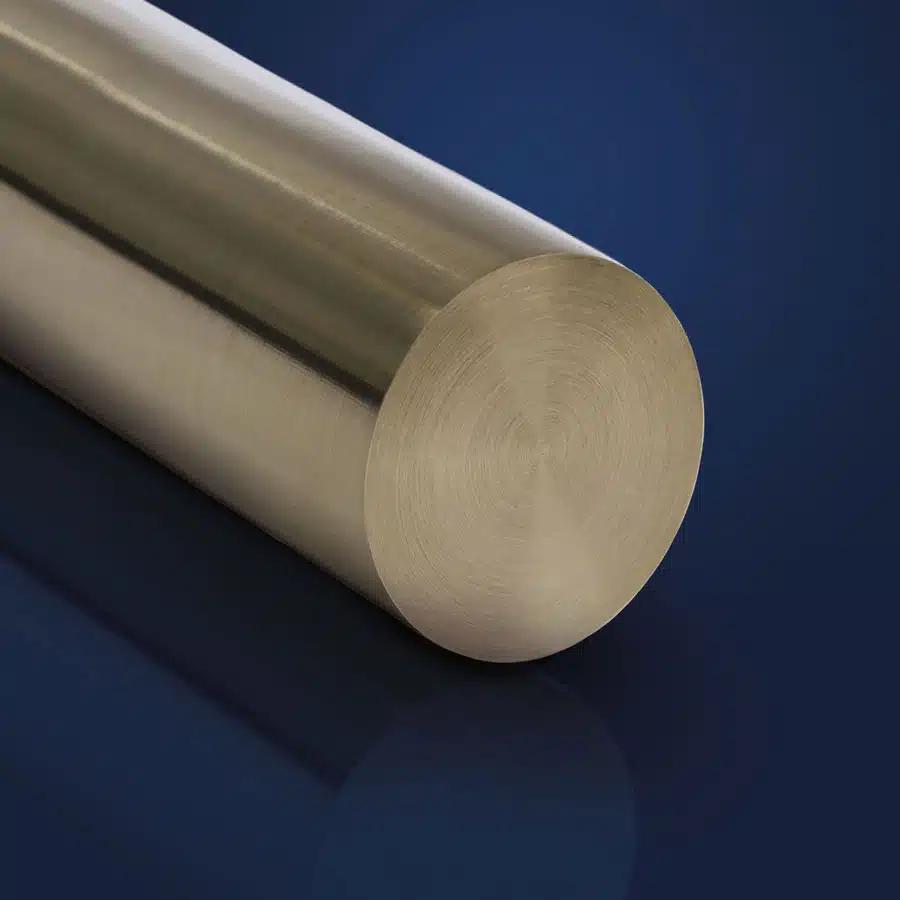

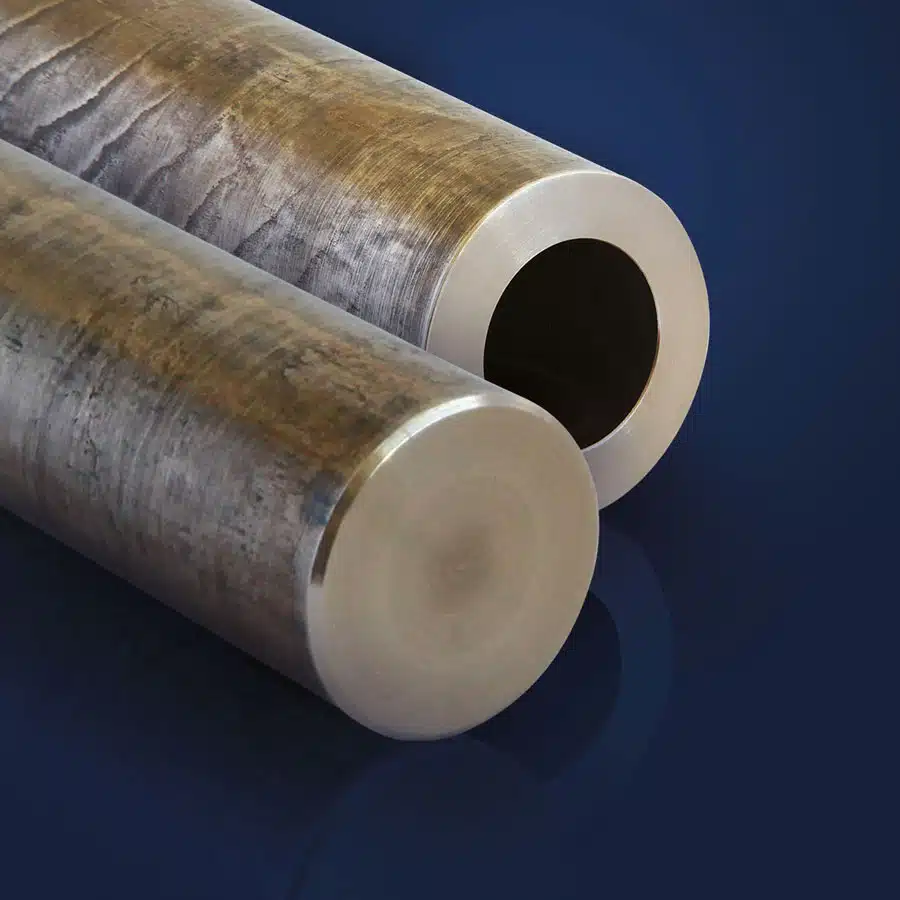

954 Aluminium Bronze

Alloy 954 is a high strength aluminium bronze that is widely used in heavy duty applications such as forestry, mining, construction & marine.

It is a very hard material which has excellent strength and wear resistance, yet still retains good machining properties.

Alloy 954 also has good resistance to impact loading, but it should be noted that proper lubrication is necessary to prevent metal to metal contact. Inadequate lubrication is likely to cause scoring or ‘galling’, and consequent damage to the

bronze component and/or other moving parts. General corrosion resistance is good but de-luminification may occur under some circumstances.

All Kormax 954 Aluminium Bronze is manufactured using finely controlled continuous or centrifugal casting techniques to ensure that hardness and strength is superior to sand-casting methods. This also means that the material has a fine grain structure and is free from porosity.