For our full range of products and services, choose the relevant catalogue.

For our full range of products and services, choose the relevant catalogue.

For our full range of products and services, choose the relevant catalogue.

View our full range of casting services.

View our full range of our services.Download Catalogue

Bronzes are copper-based alloys consisting mainly of 80 – 95% copper with other alloying elements, including tin, silicon, nickel, aluminium, iron, zinc, or manganese. Because of the wide range of bronze alloys and compositions, bronze is a versatile and widely used material. Bronze is a highly ductile material and exhibits relatively lower friction against other metals. Bronze is the most preferred material when high strength, hardness, wear resistance, and corrosion resistance are required, especially in marine applications. Because bronze is both strong and versatile, it is commonly used for sacrificial bushings.

Bronze bushings and wear pads have a long service life and are resistant to shock, impact, wear, and corrosion. To reduce friction and wear, they require an external lubricant, such as grease or oil, both during installation and operation. Kormax, with over 75 years of Foundry experience, is a reliable partner for large Bronze Alloy castings. Alloy selection, component design, manufacturing, and semi-finished material supply are among our areas of expertise. Kormax is well equipped for rapid and large-scale production due to its large inventory.

Leaded Bronze alloys combine lead, tin, and zinc to create a range of alloys suitable for bearings, gears, sliding pads, and other light-duty applications. Leaded Bronzes provide light to medium duty strength, good machining properties, and are corrosion resistant.

There are several alloys available, including C932 (SAE660), which have high levels of lead and tin to provide good lubricity. Leaded Gunmetal Bronzes such as LG2 (C836) have greater zinc content for slightly higher tensile strength.

Aluminium Bronze (typically containing 9 % to12% aluminium and up to 6% iron and nickel) is a family of high-strength, corrosion-resistant bronzes. It also offers excellent hardness, good wearing qualities, good fatigue resistance, and is well suited for applications at elevated temperatures.

These properties make Aluminium Bronze alloys suitable for heavy duty industries such as forestry, mining, and marine. Applications include heavy-duty sleeve bearings, machine tool ways, pump and valve components handling sea water, engine components, and industrial process fluids.

Phosphor Bronze alloys contain copper, between 0.5% and 11% tin and 0.01% to 0.35 % phosphorus. Adding tin increases the corrosion resistance and strength of the alloy, whilst the phosphorus increases the wear resistance and stiffness of the alloy.

Phosphor Bronze, also known as ‘gear bronze’, are high strength alloys with excellent resistance to corrosion and fatigue, have exceptional elastic qualities, low coefficient of friction, good electrical conductivity, and are readily formable, castable, and solderable. They are used in applications such as sleeve bearings, shafts, gears, thrust washers, and valve parts.

Manganese bronze alloys contain additives of manganese, iron, aluminium, and lead to achieve extra high strength and excellent corrosion resistant properties. These properties, with the inclusion of lead for lubricity, make it commonly used for bearings operating with heavy loads.

Kormax offers 863 Manganese Bronze. In terms of high-performance in heavy load applications, Kormax’s 630 Nickel Aluminium Bronze is also highly capable due to its manufacturing method of extrusion giving it superior strength.

As a fourth-generation family-owned business, Kormax brings over 75 years of Foundry and Engineering Metals experience to your project.

Kormax operates in various sectors across the world, utilising our leading engineering, manufacturing, and global distribution capabilities to offer world-class solutions for engineers.

Trusted advice on metal and profile selection for your application

Unique range of quality products, in industry specific profiles and sizes

Global top-tier supply network with the ability to source specific sizes and metals

Custom supply options and to enhance your supply continuity

ISO Certified for ISO 9001, ISO 14401 and ISO 45501 ensures quality systems are in place

With a wide supplier network, Kormax can balancing quality and value

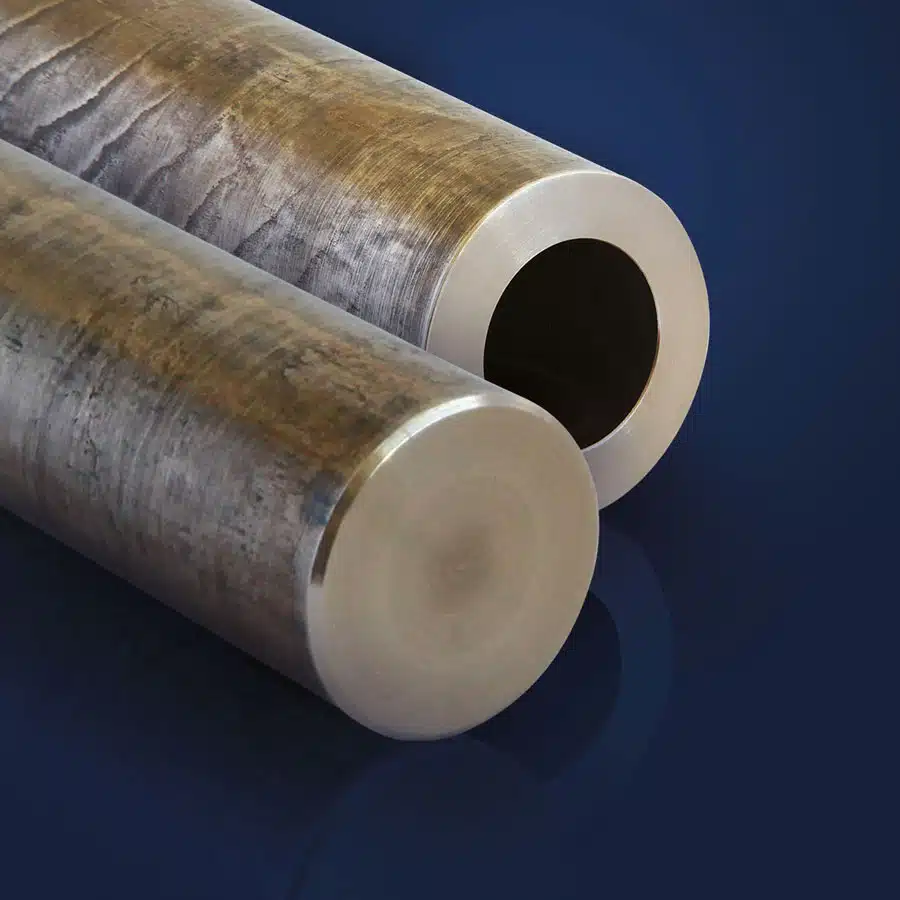

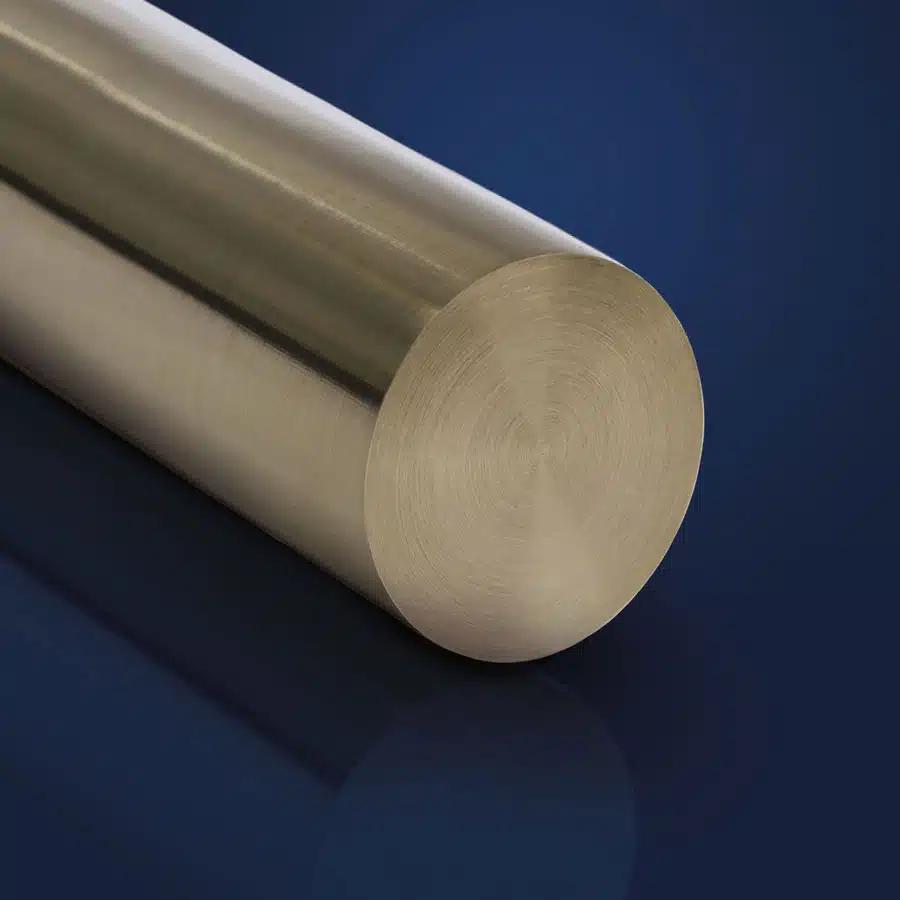

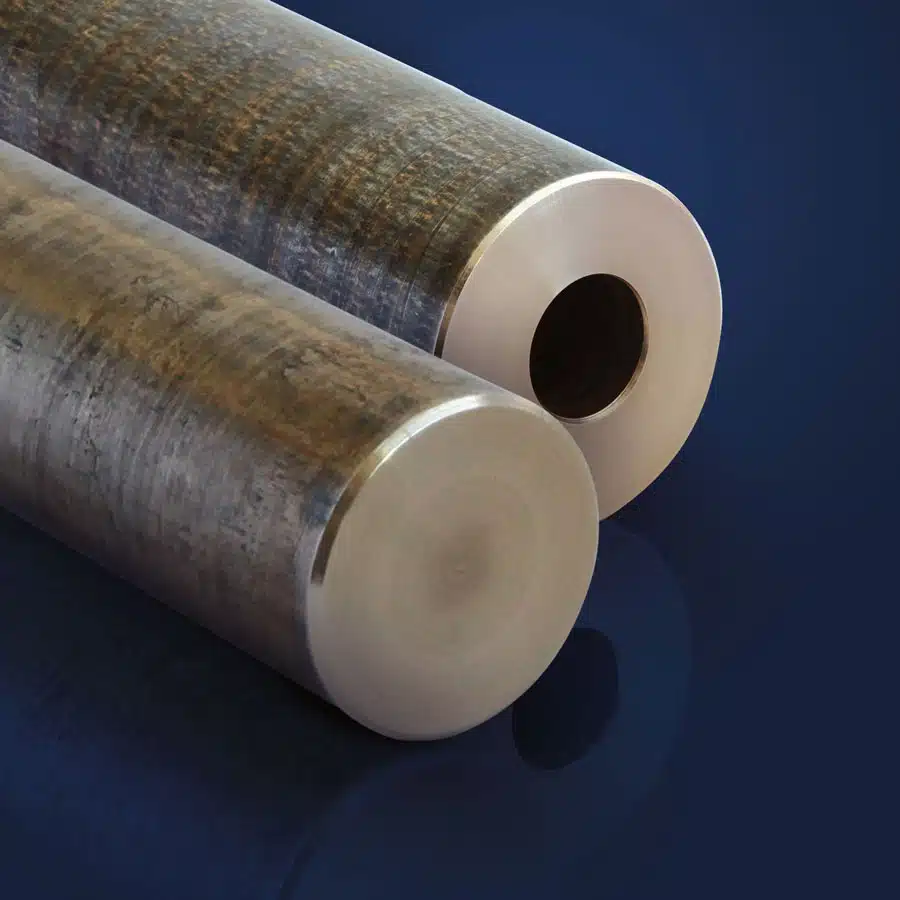

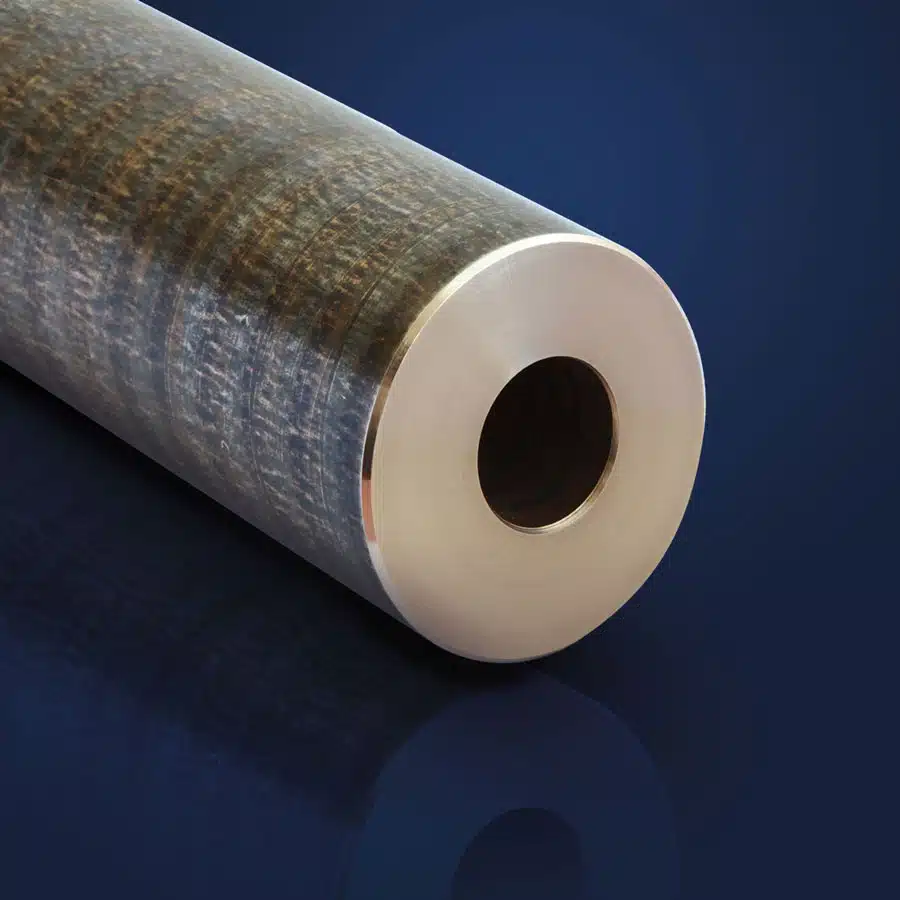

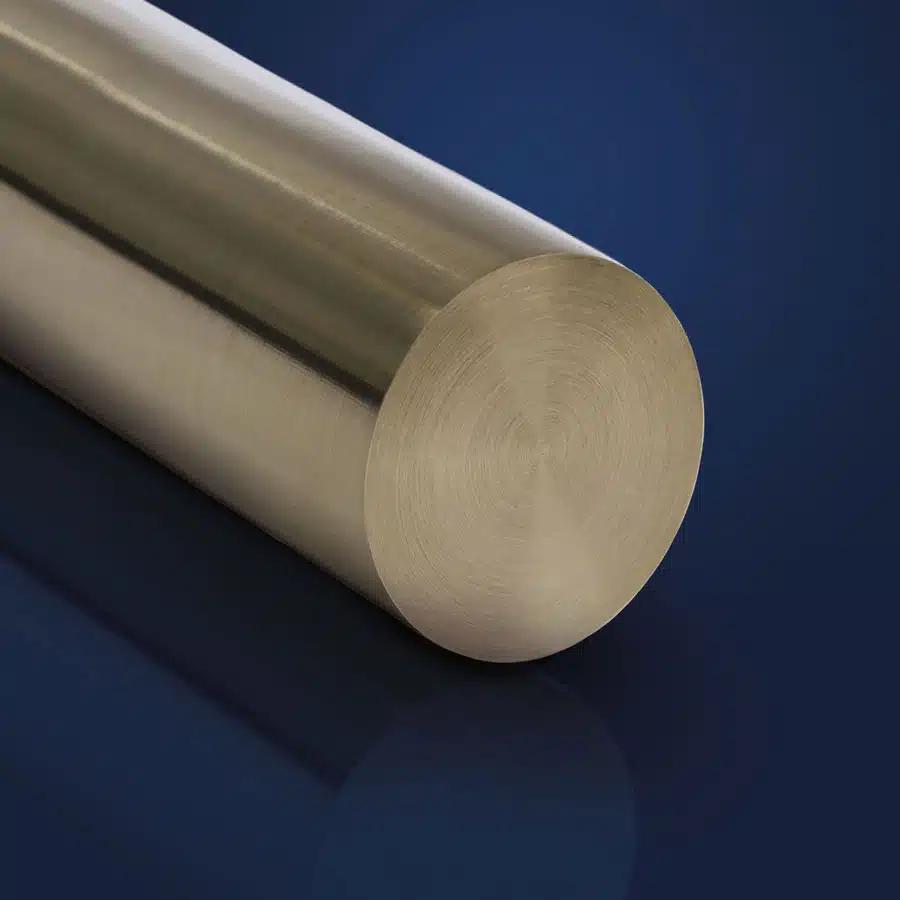

Kormax bronze is manufactured using finely controlled production methods of either extrusion, or more commonly continuous/centrifugal casting techniques. Continuous and Centrifugal casting methods ensure that hardness and strength are superior to sand-casting. It also means that the material has a fine grain structure and is free from porosity. Continuous casting can produce bars of solid round, hollow round, flat, and square amongst others from ½”/12.7 mm up to 18”/457.2 mm. Centrifugal casting is employed for making hollow round profiles up to 236”/6000 mm diameter.

Kormax can also obtain Extruded Bronze, which produces a highly consistent grain structure as well as higher tensile strength than other casting methods. Extruded Bronze is typically used for highly critical components such as aircraft undercarriage components and superyacht fittings.

Kormax can source the best Bronze alloy in the most optimal profile and size for your project and custom sizes and profiles are available upon request.