Initial project meeting to understand your product specifications.

For our full range of products and services, choose the relevant catalogue.

For our full range of products and services, choose the relevant catalogue.

For our full range of products and services, choose the relevant catalogue.

View our full range of casting services.

View our full range of our services.Download Catalogue

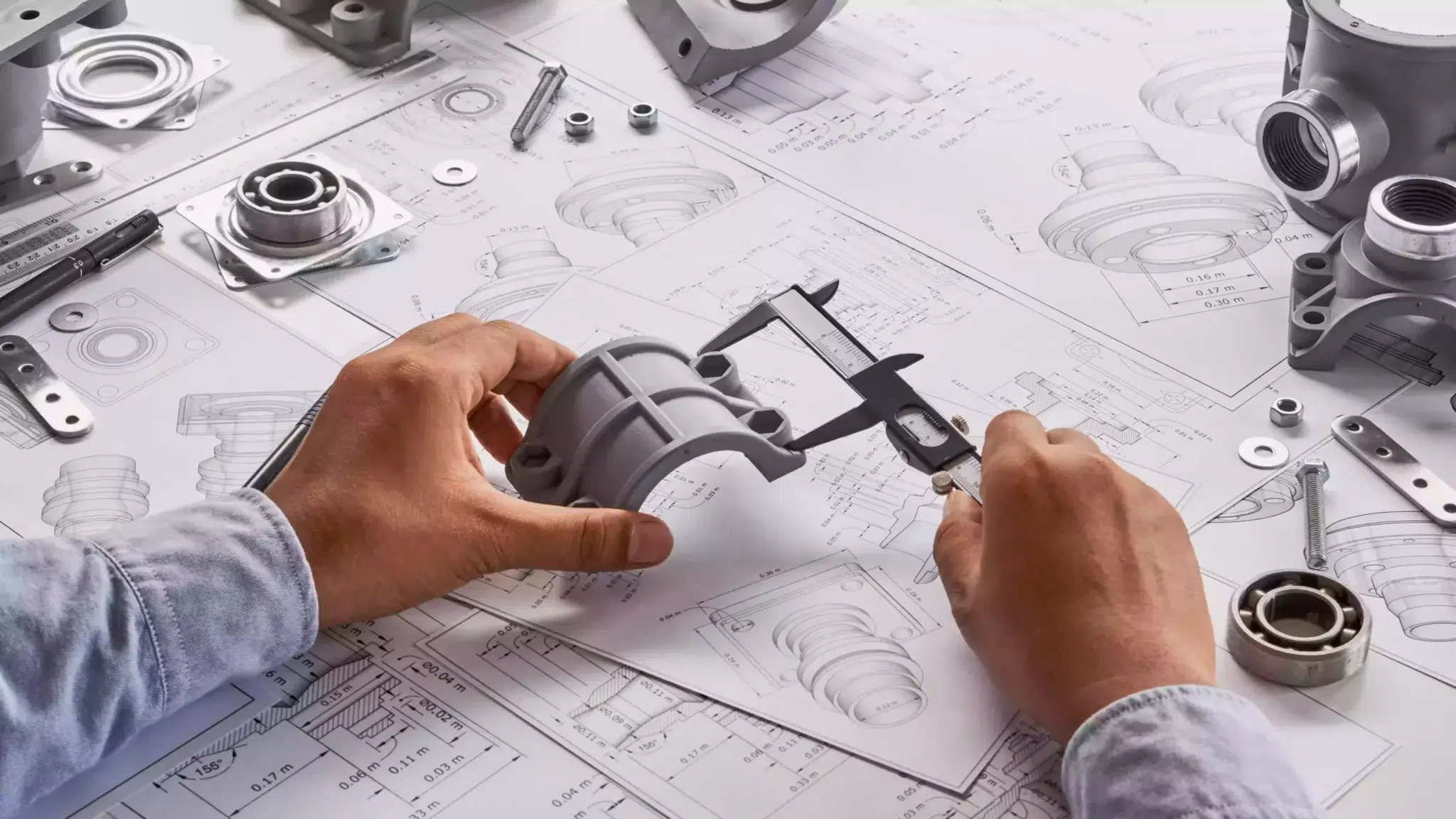

Kormax’s experienced and expert staff ensures that the best casting method and the best foundry, from our top-tier manufacturing facilities, are selected for your product’s requirements.

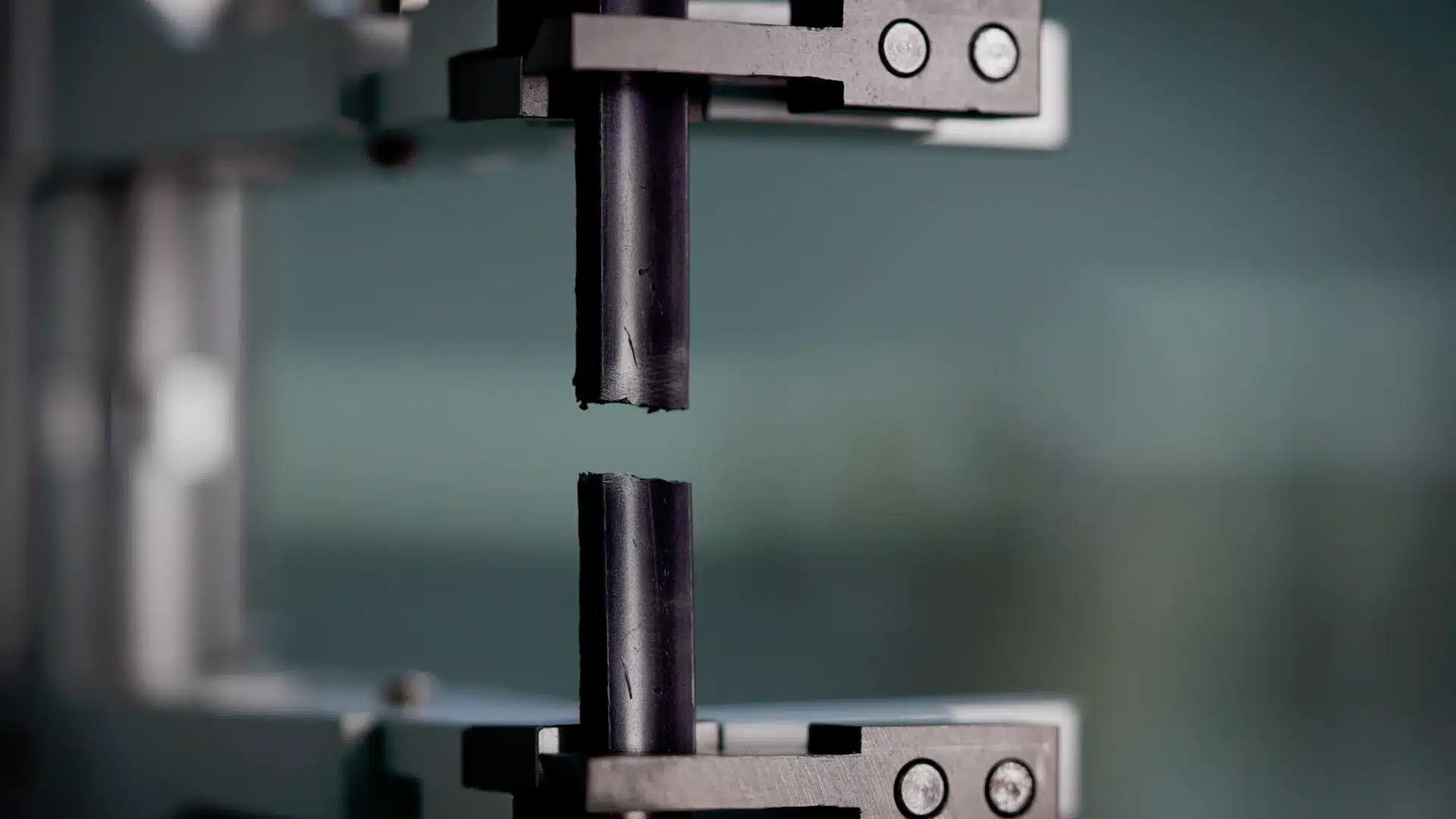

Our flexible and proven process is designed to minimise risk for our customers. With robust quality management procedures throughout the whole process, from design to patternmaking, and sample approval to final production, Kormax customers can have confidence that their products are made to meet their specifications, at the highest level of quality, repeatedly.

Initial project meeting to understand your product specifications.

Project plan is created, and our engineering team is briefed.

Kormax assists your engineering team with design optimisations.

Casting models and pricing options are presented to you.

Iterations are made to meet all design and quality requirements.

Final drawing signoff takes place and contract details are finalised.

Production takes place and delivery arranged to agreed dates.

Trusted to help customers make informed and profitable decisions.

As a fourth-generation family-owned business, Kormax brings 75 years of Foundry and Engineering Metals experience to your project.

Offering diverse production capabilities and a broad range of alloys, our customers trust us for delivery of quality cast and finished products to industry and customer specifications. Combining our understanding and experience with a large range of casting methods and alloys – our value-adding, creative solutions mean we have a way of making the “complex” simple and improving our customers’ design outcomes.

Kormax’s expert team can be trusted for a full-service solution – from design advice, to best matching a product’s specific requirements with the correct alloy, optimal casting process, and best foundry for the job, and within budget.

Est. 1947. We have over 75 years of Foundry production and metals experience

De-risking supply chain with customised solutions to best suit customers’ needs

Seamless casting development and quality procedures to minimise risk

Knowledgeable and experienced advice on alloy selection, manufacturing process, and design

Best foundry selected with capabilities to deliver your product’s specified requirements

No bias to any particular casting process – balancing quality and value

ISO Certified for ISO 9001, ISO 14401and ISO 45501 ensures quality systems are in place

Processes in place to protect your intellectual property

Good value pricing and low-cost tooling

With diverse production capabilities and a broad range of alloys, our customers trust us for delivery of quality cast and finished products to industry and customer specifications.

Balancing quality and value is non-negotiable, and what we do. 3rd party quality control and ISO certified for ISO 9001, ISO 14001, and ISO 45001. Options include:

See how we help our customers achieve their engineering victories.

Kormax went above and beyond to expedite 5 x units in a quick turnaround. The quality of the bronze and cast iron casting, machining, and service I would recommend to anyone. Looking forward to our next casting project

Kormax has exceeded our expectations for our Casting supply. They have helped enhance our product design, assisted with metallurgy and have offered fast and professional service. We wouldn’t have a doubt recommending them to any serious casting buyer.

They not only know their products but also understand the application of them, which is vital to ensuring our customers are delighted with the beautifully crafted pieces we deliver.

Kormax is great to deal with, good with their communications and never leaves us in the lurch. I would be happy to recommend Kormax.

Dealing with Kormax since late this year has been a pleasure. Good service, advice, and competitive pricing. Staff are a pleasure to deal with. Courteous, helpful, and obliging.