We have recently started buying material from Kormax and they have been a pleasure to deal with. Kormax believe in exceptional customer service which is so rare these days. Keep up the good work.

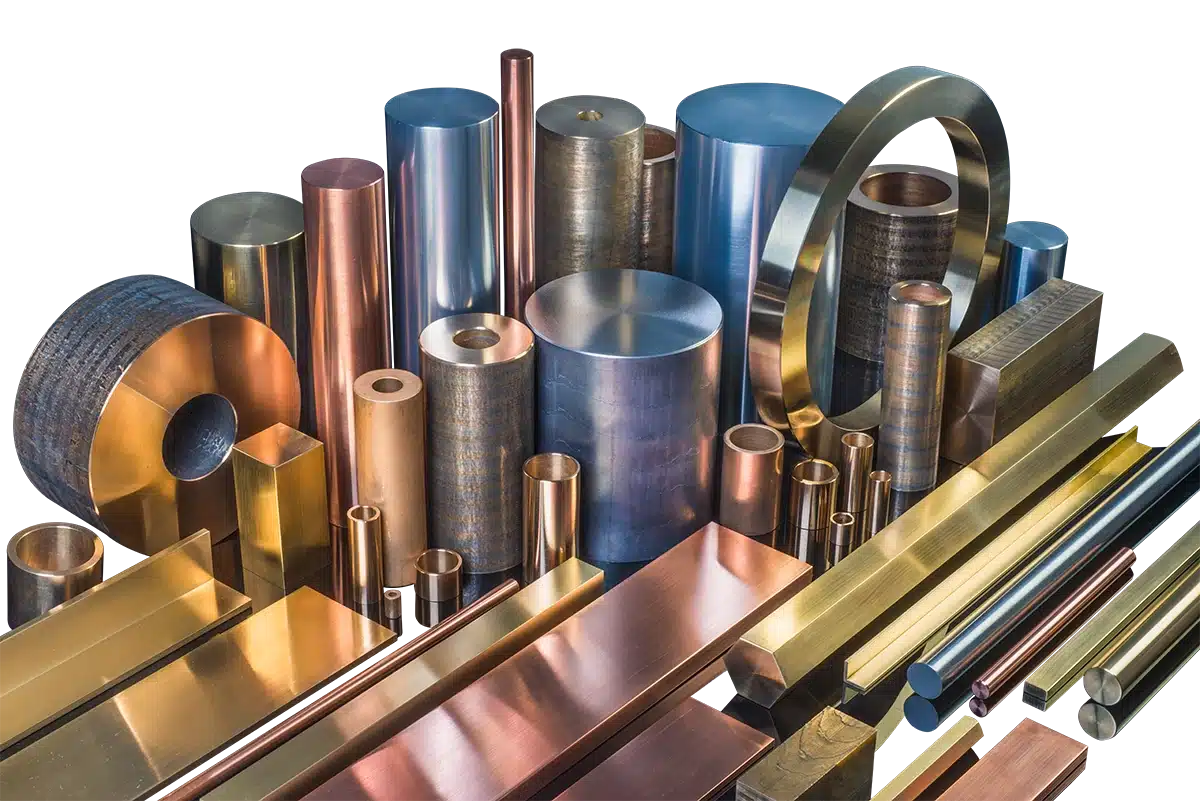

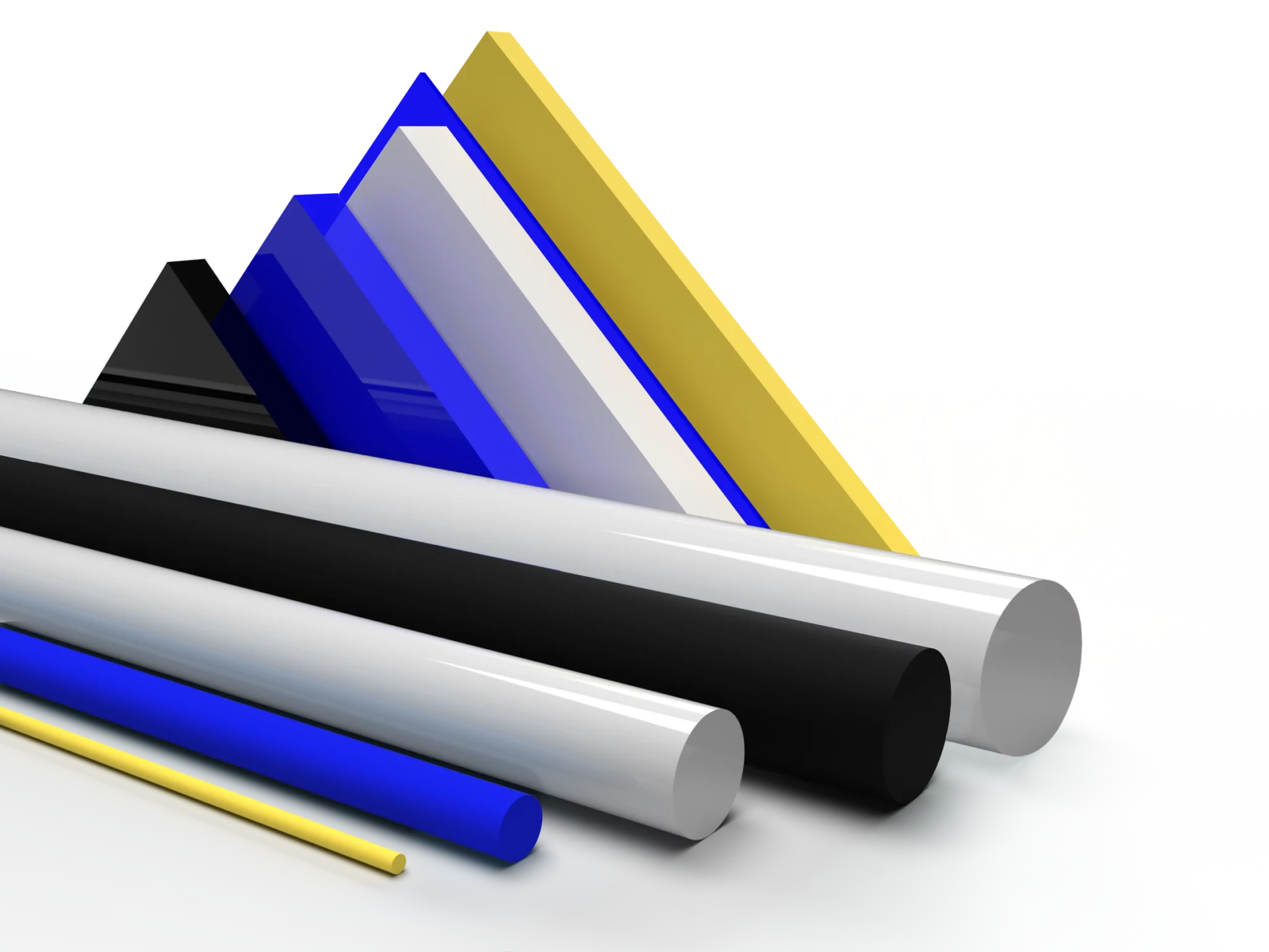

For our full range of products and services, choose the relevant catalogue.