For our full range of products and services, choose the relevant catalogue.

For our full range of products and services, choose the relevant catalogue.

For our full range of products and services, choose the relevant catalogue.

View our full range of casting services.

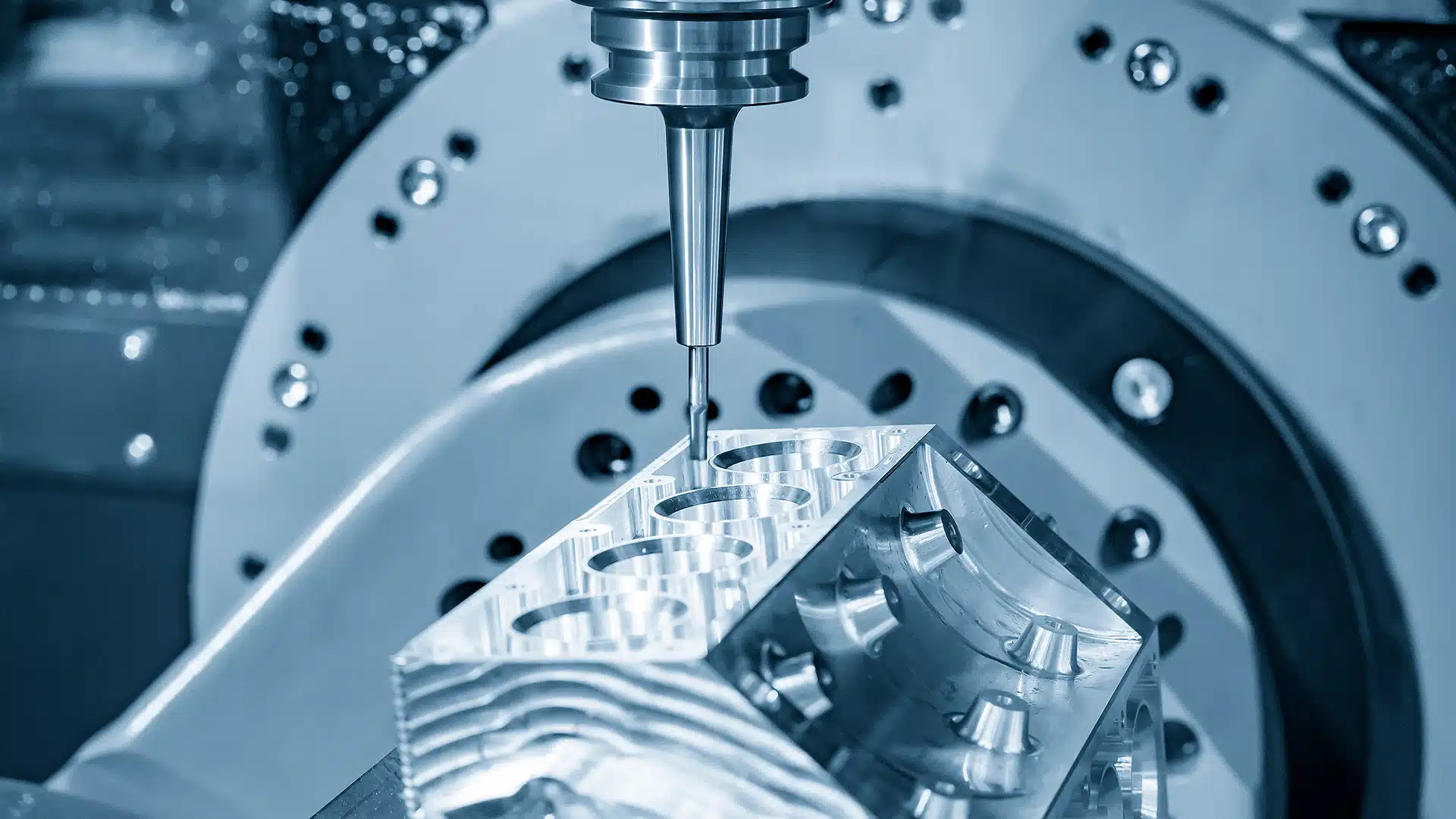

View our full range of our services.Download Catalogue

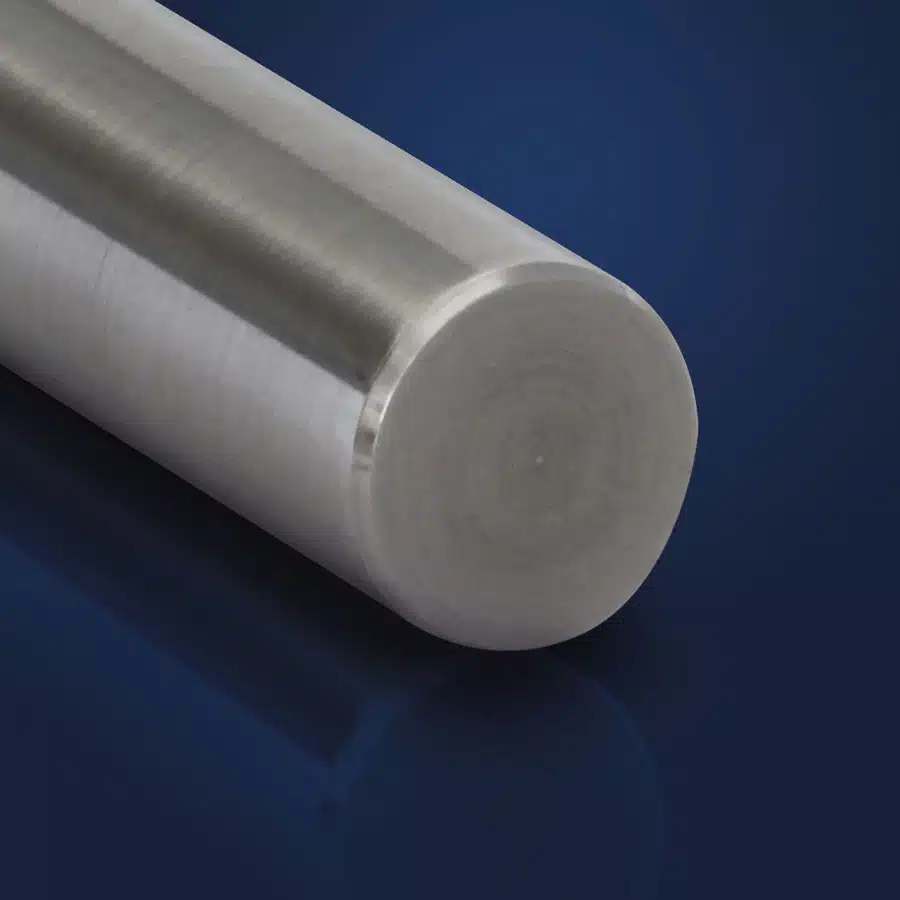

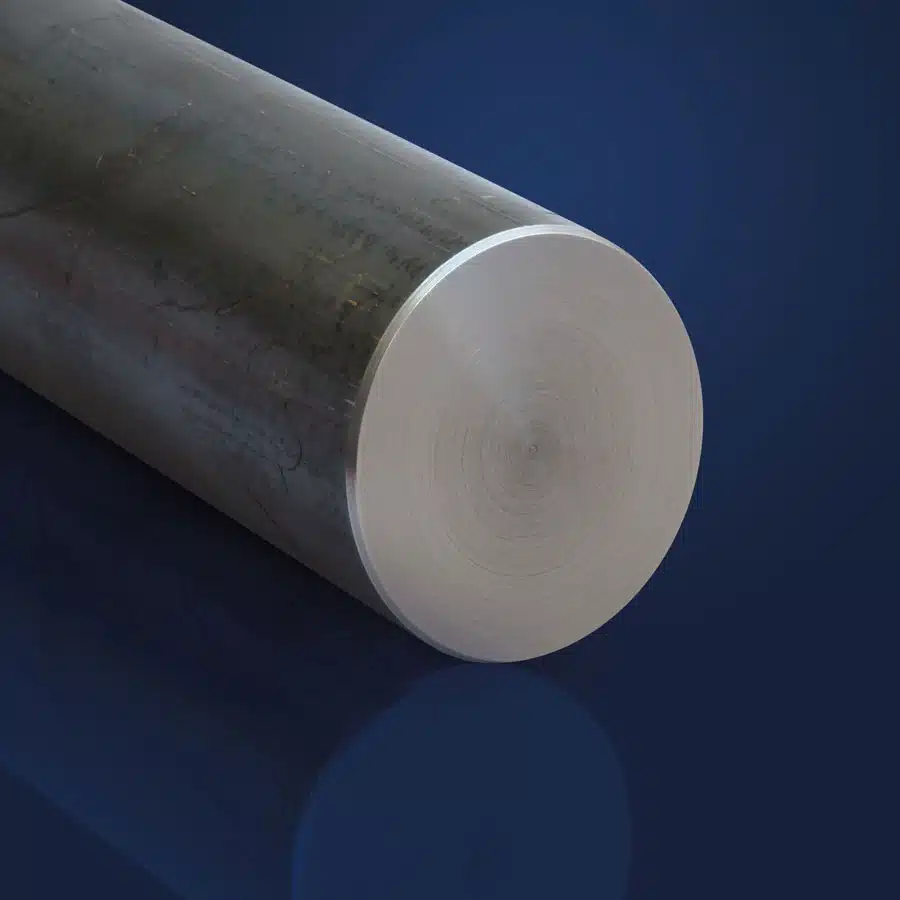

Vital for industries using structural components, due to its strength to weight ratio, low density, and corrosion resistant properties.

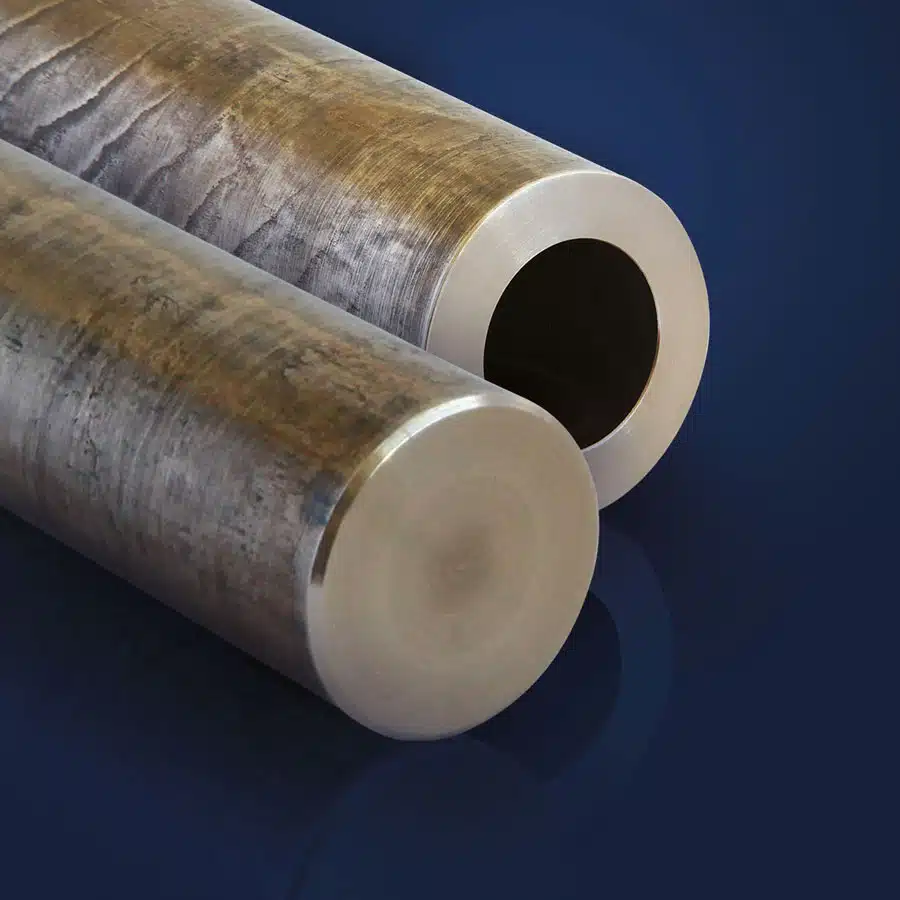

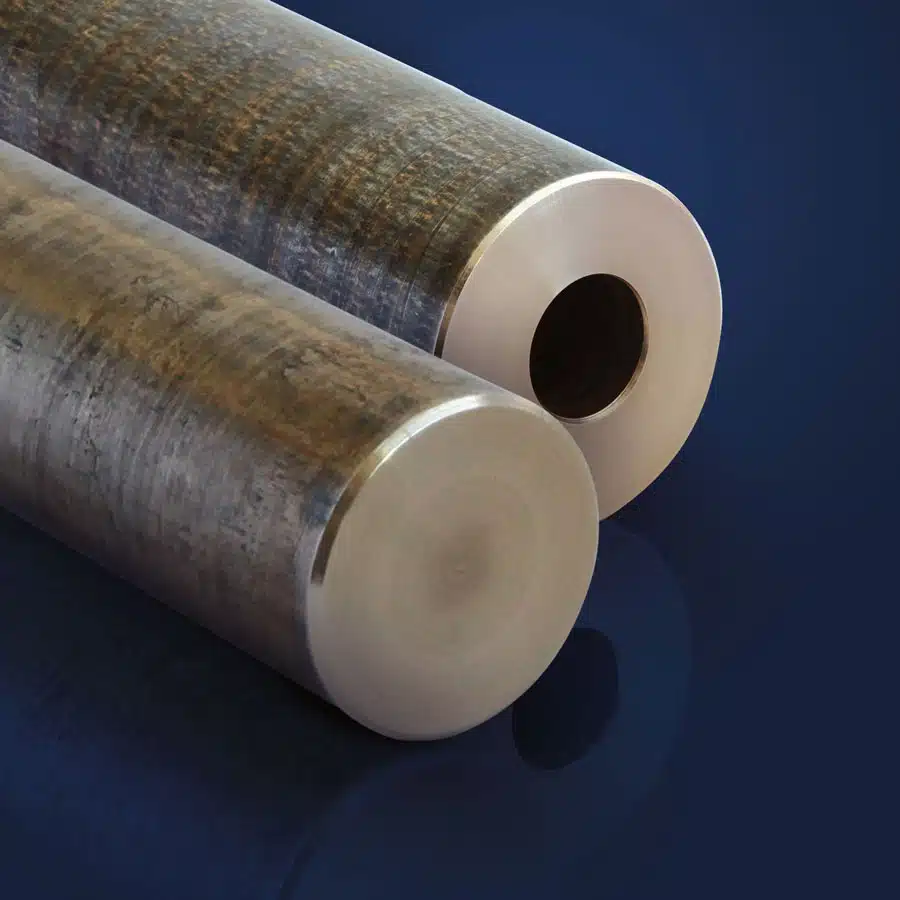

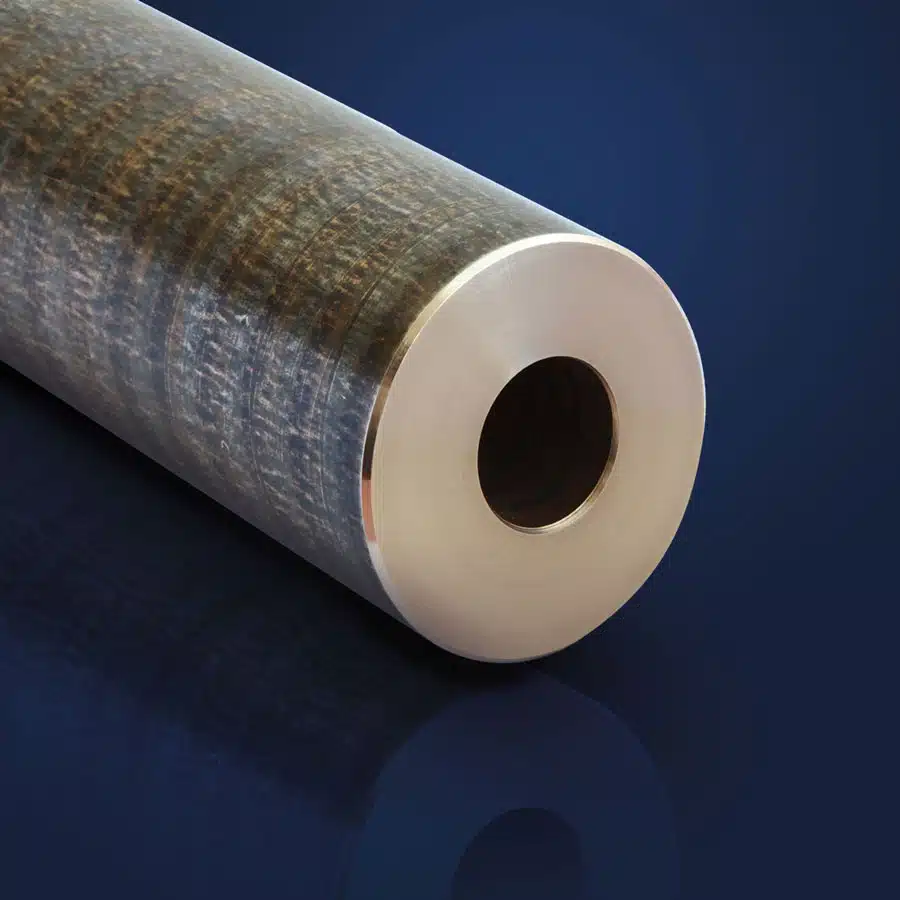

Favoured material when strength and corrosion resistance are called for and for bearing and sliding applications. Commonly used in marine hardware, pump and valve bodies, gears, etc. Bronze is infinitely recyclable ensuring it can be reused time and again.

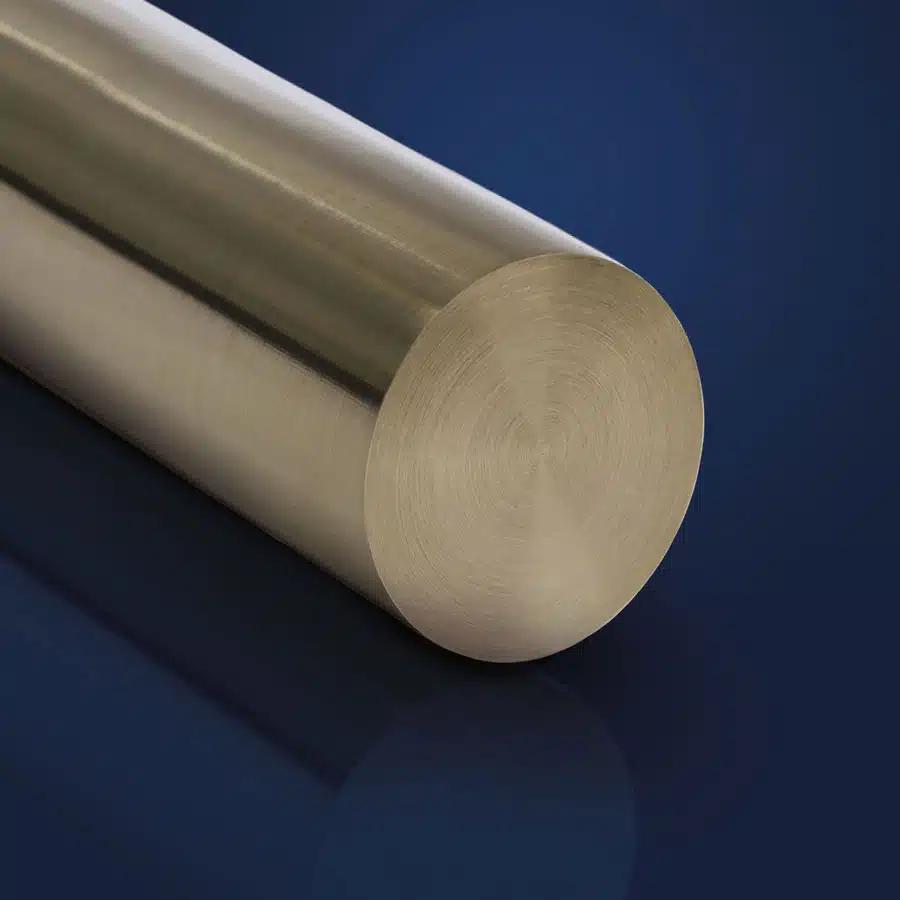

Highly machinable, formable and corrosion-resistant making it commonly used for plumbing fittings, architectural hardware, fasteners, etc.

Due to Copper’s thermal and electrical conductivity, it is widely used in conductors, gaskets, heat exchangers, radiators, etc.

Cast Iron’s properties include having vibration dampening properties making it ideal for structural components of machine tools and automotive components.

Some of Titanium’s key properties are its strength to weight ratio and corrosion resistance characteristics. Commonly used in marine sports, super yachts, and aerospace applications.

As a fourth-generation family-owned business, Kormax brings over 75 years of Foundry and Engineering Metals experience to your project.

Kormax operates in various sectors across the world, utilising our leading engineering, manufacturing, and global distribution capabilities to offer world-class solutions for engineers.

Trusted advice on metal and profile selection for your application

Unique range of quality products, in industry specific profiles and sizes

Global top-tier supply network with the ability to source specific sizes and metals

Custom supply options and to enhance your supply continuity

ISO Certified for ISO 9001, ISO 14401 and ISO 45501 ensures quality systems are in place

With a wide supplier network, Kormax can balancing quality and value

View our Metals Book for the full range of Kormax’s Engineering Metals and contact Kormax’s knowledgeable staff for assistance in choosing the right alloy for your product’s specific application.

Download the full Metals Book.